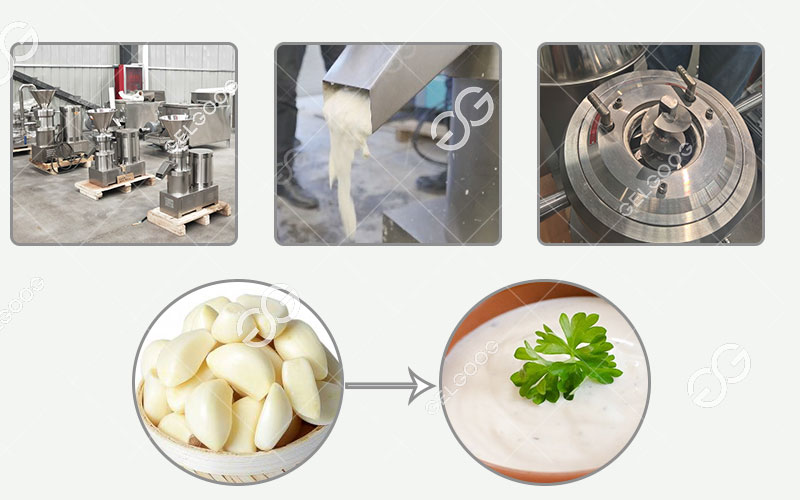

Introduction Of Garlic Grinder Machine

The ginger garlic paste grinding machine grinds garlic into garlic sauce through ultra-fine grinding and emulsification, using food-grade materials, and the ground garlic paste can be eaten directly. And garlic grinder machine can grind a variety of fruits and vegetables into sauce, including peanuts, peppers, tomatoes, ginger, mango materials, and has the advantages of multi-function, wide application and high cost performance.

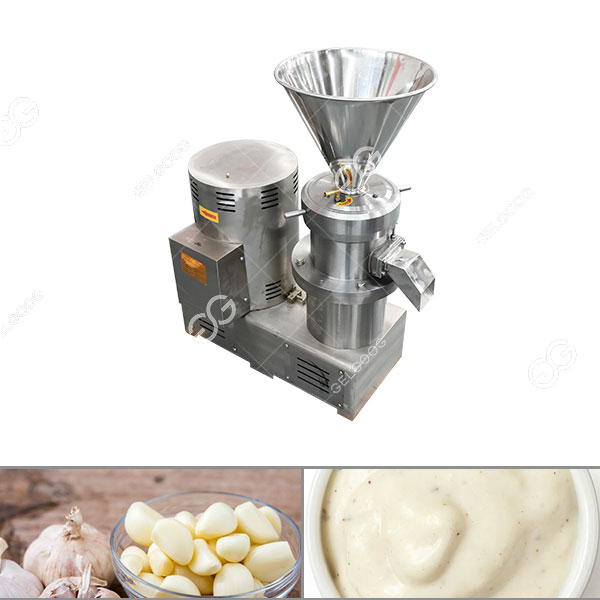

Features Of Garlic Paste Grinding Machine

1. The internal structure setting is optimized and the grinding disc is firm and wear-resistant.

2. Adopt explosion-proof motor to ensure safe use.

3. The machine can be customized with different models, 220V voltage or 380V voltage can be used, depending on the model.

4. The garlic grinder machine can add a universal wheel to achieve convenient movement.

Advantages Of Ginger Garlic Paste Grinding Machine

1. Made of stainless steel,ginger garlic paste grinder machine has a long service life and will not pollute the garlic.

2. Compact structure, stable operation and low noise.

3. Small size, small footprint, easy to use and store.

4. The grinding efficiency is high, when the material is put in, garlic ginger grinder machine can be made into sauce in 1 second.

5. The garlic paste grinding machine can be adjusted to control the thickness of the finished particles.

6. The dry garlic grinding machine can be cleaned with water directly.

7. It can be used in food industry, chemical industry, pharmaceutical industry, daily chemical industry, construction industry and other industries.

How Garlic Grinder MachineWorks

The colloid mill is driven by a motor, which drives the rotating teeth (or called the rotor) and the matching fixed teeth (or called the stator). There is an adjustable tiny gap between the two grinding bodies. When the material passes through this gap, a sharp velocity gradient is generated, so that the material is subjected to physical effects such as strong shearing, friction, high-frequency vibration, high-speed vortex, etc., so that the material is effectively emulsified, dispersed, homogenized and pulverized.

Parameters Of Electric Garlic Grinder

| name | model | Material processing finances(um) | output(t/h) | power of motor (kw) | External size

(mm) |

weight (kg) |

| Colloid mill | GG-JMS-50 | 2-50 | 0.005-0.03 | 1.1/1.5 | 530×260×580 | 70 |

| GG-JMS-80 | 0.07-0.5 | 4 | 680×380×930 | 210 | ||

| GG-JMS-110 | 0.3-1.2 | 7.5 | 750×450×1000 | 280 | ||

| GG-JMS-130 | 0.4-2.0 | 11/15 | 990×450×1100 | 400 | ||

| GG-JMS-180 | 0.8-6.0 | 18.5/22 | 1000×480×1150 | 450 | ||

| GG-JMS-240 | 4.0-12 | 37/45 | 1330×650×1300 | 1000 | ||

| GG-JMS-300 | 6.0-25 | 75/90 | 1450×630×1420 | 1600 |

Garlic paste grinding machine is the most necessary machinery in the garlic paste production line. If you are starting a new business in garlic paste processing, you can also customize our garlic paste production line and we will provide you with a solution. If you are interested, you can leave a message online.

Reviews

There are no reviews yet.